|

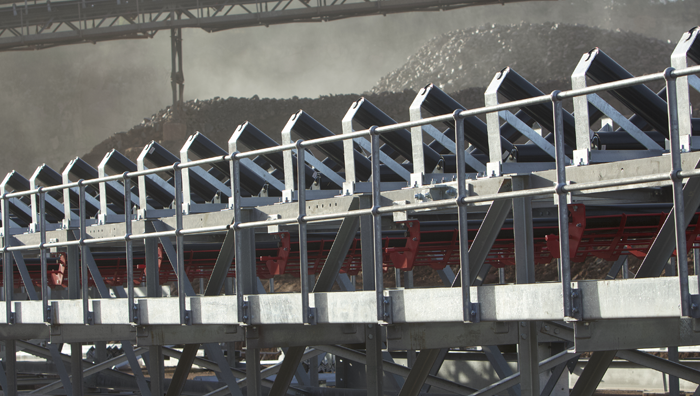

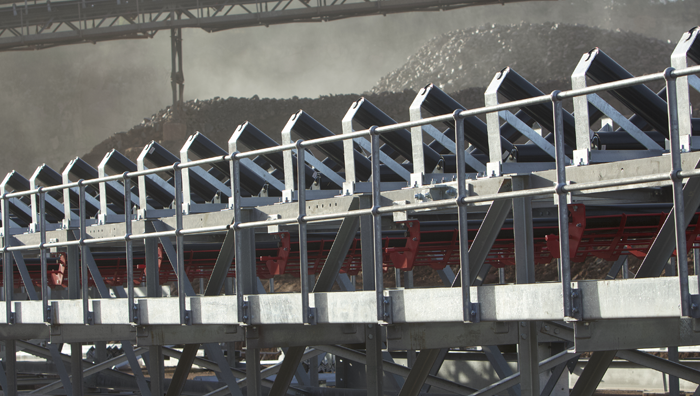

When choosing a transom for your bulk handling conveyor system, there are a few factors to consider:

The size and weight of the conveyor belt: The transom must be strong enough to support the weight of the conveyor belt and its contents.

The type of material being conveyed: Some materials, such as abrasive materials, can put additional stress on the conveyor belt and transom.

The operating environment: If the conveyor system is operating in a harsh environment, such as a dusty or corrosive environment, the transom must be made of a durable material that can withstand the elements.

Our technical team can advise on choosing the most suitable transom for your conveyor system. Some of the factors that they will considere are the size and weight of the conveyor belt, the type of material being conveyed, and the operating environment.

|